Douglas Fir Distribution Crossarms

BROOKS is committed to producing the highest quality crossarms available in the industry. Our products are available in a wide variety of sizes and applications and meet all industry standards. Our reputation for manufacturing quality crossarms has been earned through years of active involvement working with utilities and industry associations to develop standards which meet the critical demands of the electric utility industry.

Our fully integrated high efficiency manufacturing facility, located in the heart of the timber industry, provides total control of purchasing, grading, seasoning, boring, and treating operations. Our veteran lumber graders and skilled production staff understand timber characteristics and our multiple inhouse inspections of every piece of lumber ensure our crossarms meet or exceed your specifications. When you purchase distribution crossarms from BROOKS, you also gain the confidence of knowing our products are backed by years of experience and our commitment to provide the best products available in the industry.

Our fully integrated high efficiency manufacturing facility, located in the heart of the timber industry, provides total control of purchasing, grading, seasoning, boring, and treating operations. Our veteran lumber graders and skilled production staff understand timber characteristics and our multiple inhouse inspections of every piece of lumber ensure our crossarms meet or exceed your specifications. When you purchase distribution crossarms from BROOKS, you also gain the confidence of knowing our products are backed by years of experience and our commitment to provide the best products available in the industry.

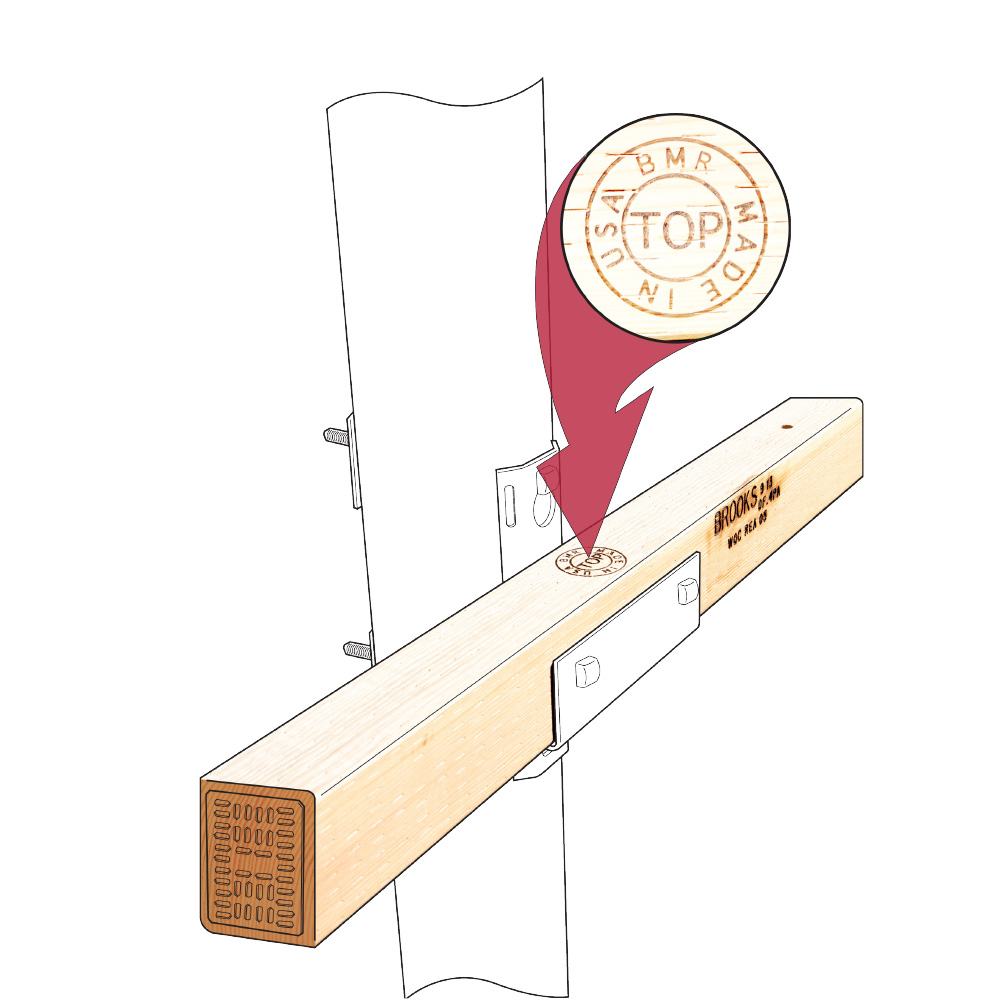

BROOKS Machine Rated (BMR)

At BROOKS Manufacturing, we’re committed to producing the best products on the market. That is why we’ve introduced the BROOKS Machine Rated (BMR) standard. To guarantee that every distribution crossarm meets our high standards, we’ve incorporated this test into our manufacturing process. As it passes through our automated drilling process, each crossarm gets stamped with an electric load cell, pre-programmed to apply stress to simulate the typical working load of a distribution crossarm in the field. The durability of the crossarm is verified through this prestressing process. It also helps us determine if there are any defects that aren’t visible in the product which may lead to breakage.

As the only wood crossarm manufacturer that performs this test, you can be assured that when you see the BMR stamp, you’re getting the quality of BROOKS Manufacturing. In addition, every crossarm has a warranty for one year from date of manufacture.